| Availability: | |

|---|---|

| Quantity: | |

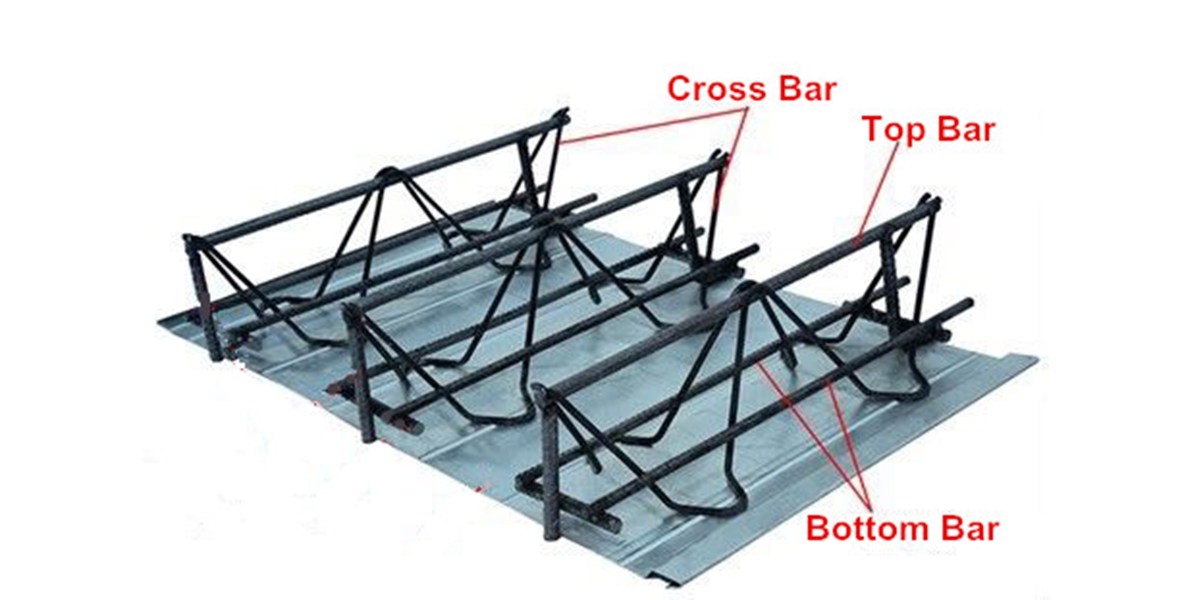

Steel-bar truss floor decking sheets are innovative composite materials revolutionizing modern steel-framed construction. Comprising cold-formed steel sheeting topped with pre-fabricated steel-bar trusses, they serve as permanent formwork and structural reinforcement for concrete slabs. Here’s a detailed breakdown:

1. Key Components & Design

Bottom Steel Sheet: Provides formwork during concrete placement and contributes to shear resistance. Steel-Bar Trusses: Welded to the steel sheet, these triangular trusses (typically with 6–12 mm diameter bars) enhance tensile strength and stiffness. Concrete Topping: Integrates with the truss system to form a composite slab, with thicknesses ranging from 100–200 mm.

2. Speedy Construction: Pre-assembled trusses reduce on-site labor and installation time by up to 50% compared to traditional formwork.

3. Flexible Reinforcement: Truss spacing and bar diameters are customizable to meet specific design requirements, adapting to varying load conditions.

4. Fire & Corrosion Resistance: Concrete encasement provides fire protection (up to 2 hours), while galvanized steel components resist corrosion.

5. Applications: High-rise buildings, commercial complexes, and industrial facilities.

Retrofitting existing structures due to reduced self-weight compared to conventional slabs.

Projects requiring rapid turnover, such as hospitals, airports, and residential towers.

6. Comparison with Traditional Methods:

Weight: Up to 30% lighter than reinforced concrete slabs, reducing foundation loads. Cost: Lower labor and material costs due to prefabrication and minimal formwork. Quality: Factory-controlled production ensures consistent truss dimensions and weld integrity.

Steel-bar truss decking sheets offer a versatile, efficient solution for modern floor systems, combining speed, strength, and design flexibility in steel structures.

Packing & loading