| Availability: | |

|---|---|

| Quantity: | |

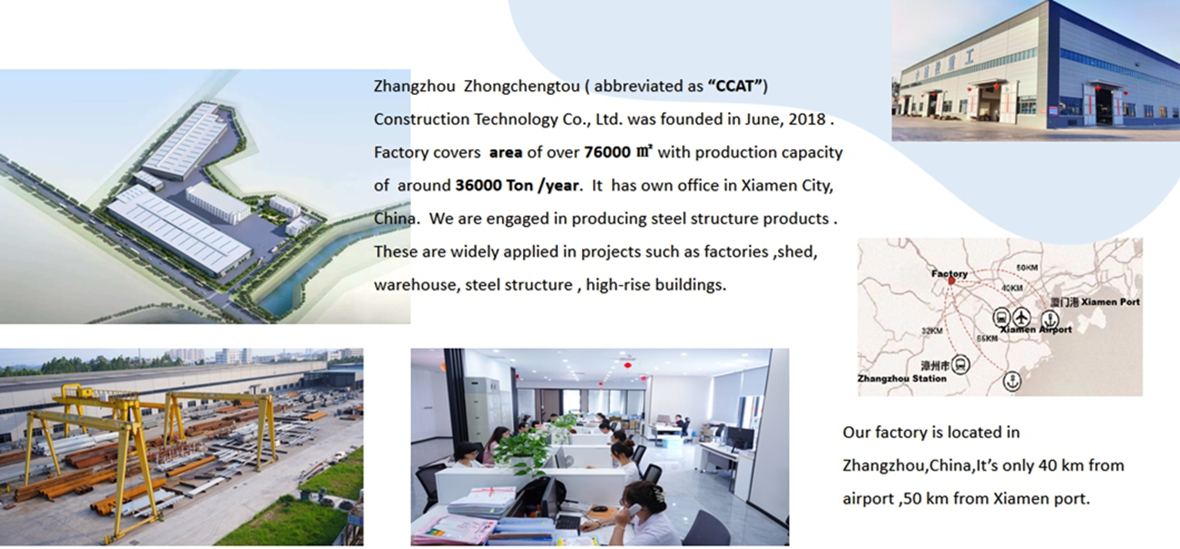

CCAT

Corrugated metal sheets are a cornerstone of modern steel-frame wall cladding, celebrated for their blend of strength, versatility, and cost-efficiency. Comprising galvanized steel, aluminum, or stainless steel formed into repetitive wave patterns, these sheets offer unique advantages for building envelopes. Here’s an in-depth look:

1. Material: Galvanized steel (zinc-coated) is standard, with aluminum or stainless steel used in corrosive environments.

2. Coatings like PVDF /SMP/HDP or PE enhance durability and aesthetics.

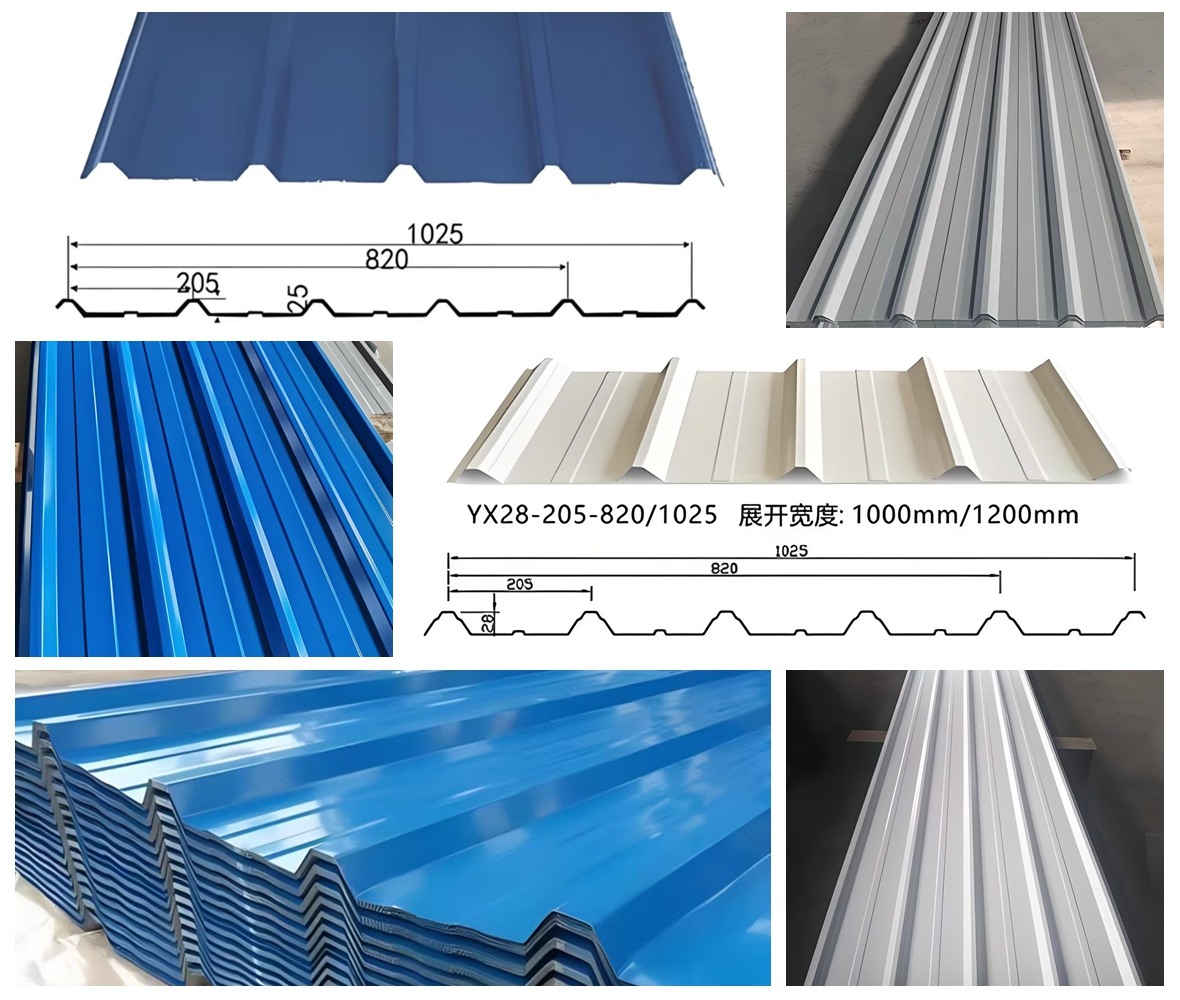

3. Profile Geometry: Wave heights range from 20–100 mm, with pitches (peak-to-peak distances) of 100–300 mm. Deeper corrugations increase stiffness, enabling longer spans between supports.

4. The corrugated shape amplifies load-bearing capacity, reducing reliance on intermediate purlins. Spans of up to 3 meters are achievable, cutting steel framework costs.

5. Weather Resistance: Overlapping panels with sealed joints create a watertight barrier. Vertical installation maximizes water runoff, while horizontal layouts (with proper flashing) suit modern aesthetics.

6. Fire & Impact Resilience: Non-combustible steel cores meet fire codes, and the rigid profile withstands extreme weather, hail, and physical impacts.

7. Cost-Effectiveness: Lightweight panels reduce shipping and labor costs. Installation is 30% faster than masonry, with minimal maintenance required over their 20–30-year lifespan.

8. Applications

Industrial & Agricultural: Warehouses, factories, barns, and cold storage facilities.

Commercial & Residential: Modern offices, retail facades, and rustic-inspired homes.

Temporary Structures: Disaster relief shelters and modular buildings.

9. Aesthetic Customization:Available in over 50 colors, with embossed or smooth finishes to match architectural visions.

10. SustainabilitySteel is 100% recyclable, aligning with green building standards.Reflective coatings reduce solar heat gain, lowering energy costs.

Corrugated metal sheets embody the marriage of form and function in steel structures. Their ability to deliver durability, speed, and design flexibility makes them indispensable for projects ranging from utilitarian warehouses to cutting-edge urban architecture.

Packing & Loading