| Availability: | |

|---|---|

| Quantity: | |

CCAT

Rockwool : Non-combustible, excellent fire resistance (up to 120 minutes), and acoustic insulation.

EPS/Foam: Cost-effective insulation with varying density and fire ratings.

3. Thermal Efficiency: Low U-values reduce heating/cooling costs, meeting strict energy codes.

4. Speed of Installation: Pre-cut panels with interlocking joints enable rapid assembly, minimizing labor and downtime.

5. Structural Performance: High strength-to-weight ratio reduces steel frame loads, optimizing foundation design.

6. Fire & Weather Resistance: rockwool cores offer Class A fire ratings; metal skins withstand corrosion, UV radiation, and extreme temperatures.

7. Design Flexibility:Available in custom lengths, colors, and profiles to suit architectural styles.

8. Applications

Industrial Buildings: Warehouses, factories, cold storage facilities.

Commercial Spaces: Offices, retail outlets, airports.

Residential Construction: Prefab homes, modular buildings.

Cleanrooms & Healthcare: Hygienic, non-porous surfaces resist microbial growth.

Sandwich panels combine insulation, durability, and aesthetics, making them a versatile solution for modern, high-performance building envelopes.

Rockwool sandwich panel and its manufacturing process is one the most advanced inventions, which in the factory automation equipment, rock wool and steel into a whole, thus changing the way of the rock wool plate before the compound required site , under the premise that meet the requirements of the building thermal insulation, sound insulation, fire protection, to achieve a high quality, efficient, reliable, safe target.

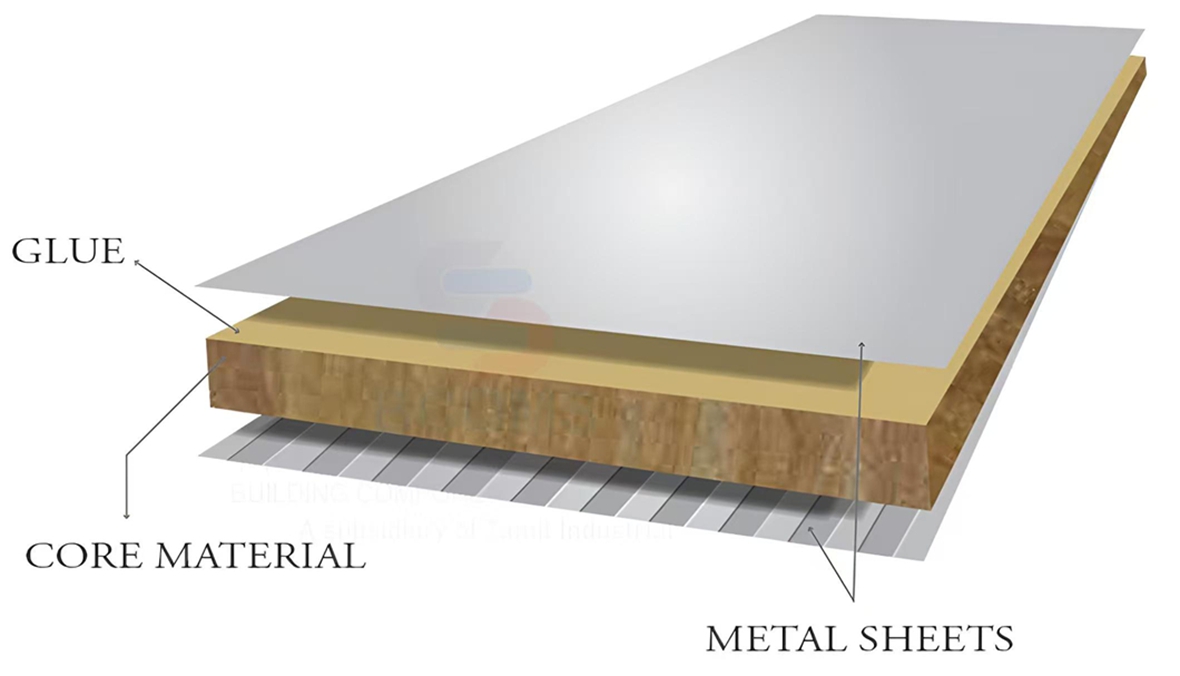

The up & down surface of this rockwool panel is Galvanized & Pre-painted steel sheets, core material is 5 components rockwool glue, it is formed by heating, foaming & laminating. Rockwool is the best material for temperature keeping and sound insulation. It is widely used as the wall or roof for cold storage, industrial workshop, public building etc.

Product Description of Sandwich panel:

Cover Width: 950mm

Length: Customized but no more than 11.8meter usually.

Up color steel board thickness: 0.4mm to 0.7mm

Low color steel board thickness: 0.4mm to 0.7mm

Total thickness: 50mm,75mm,100mm,120mm, 150mm,

Coated materials: Zinc or aluminum alloy, 60-120G/M2

Fillings: EPS, PU, fiber glass or rock wool

Steel Grade: Q235

Steel color: white, Blue or RAL color

Loading & Shipping

Certificate

Company Profile